M2M technology has been around for some time now, and it has revolutionized many industries. M2M technology provides businesses with a way to automate tasks, reduce costs, and gain insights into their operations.

M2M technology is quickly becoming an essential part of the automotive industry, providing a range of solutions that improve safety, reduce costs, and increase efficiency. Automotive companies can use M2M technology to remotely monitor and control their vehicles, track driver behavior and diagnose problems more quickly and accurately. M2M also allows for automated driving systems, providing increased safety on roads and highways. In addition, car manufacturers can use M2M technology to collect real-time data from their cars, which can be used to improve product designs, optimize service delivery, and even provide targeted marketing. By leveraging the power of M2M technology, automotive companies can ensure their vehicles are safer, more reliable, and better performing than ever before.

M2M technology is revolutionizing the healthcare industry. By providing real-time communication between medical devices, systems, and patient data, M2M technology can increase the efficiency of healthcare services and provide better patient care. One of the most important applications of M2M technology in healthcare is the monitoring of vital signs such as heart rate, blood pressure, and temperature. With M2M technology, healthcare providers can have access to real-time information on patient vital signs, making it easier to detect changes in health status and provide appropriate care. This can help to reduce hospital readmissions and improve overall patient outcomes. M2M technology can also be used to track medical supplies, from drugs and medical equipment to patient files. This helps to ensure that all medical supplies are kept up-to-date and easily accessible for both staff and patients.

Transportation has been a major beneficiary of Machine to Machine (M2M) technology. Thanks to the ability to track and monitor vehicles, companies can optimize their resources, maximize efficiency, and reduce costs. Companies such as airlines, shipping firms, and trucking companies can benefit from the use of M2M technology to monitor their fleets. M2M technology allows for real-time tracking of vehicle location and speed, as well as other important information such as fuel consumption and engine performance. This data can be used to identify trends in routes taken, which can help to optimize delivery times.

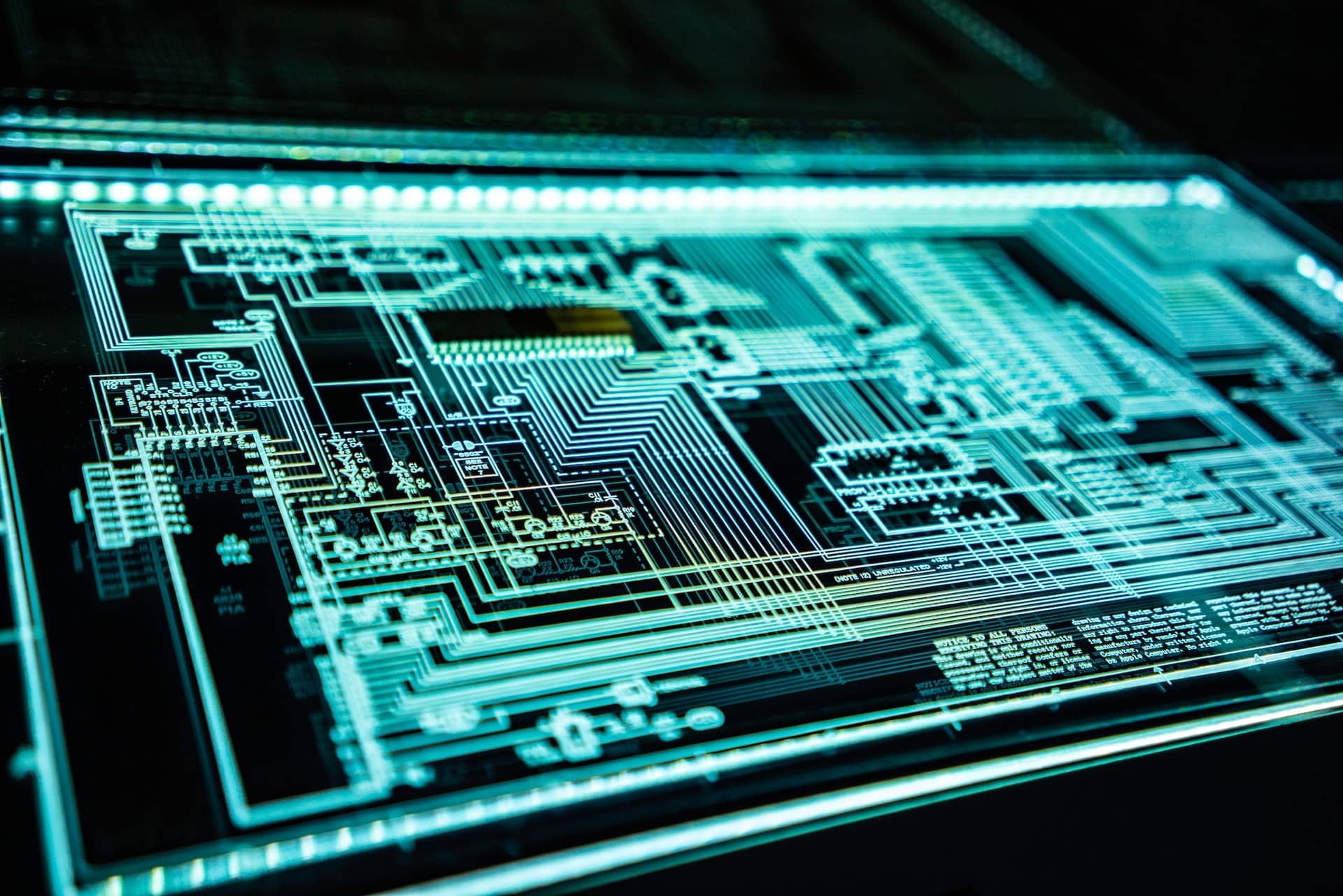

Main photo: Adi Goldstein/unsplash.com

Sponsored text